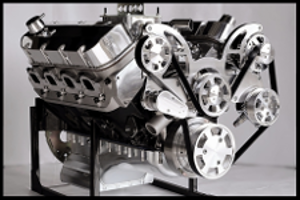

FORD NKB 190cc/62cc ULTRA HIGH FLOW CYLINDER HEADS, 289 302 347 ENGINES.

Setup for hydraulic roller cams.

190cc RUNNERS, 62cc COMBUSTION CHAMBERS.

*** IMPORTANT NOTE ***

You may add items into your shopping cart but in order to check out you will have to call us. Our check out feature on our website is being upgraded at this time. We can take your order over the phone and answer any technical questions you may have. We accept all major credit cards, cash, check, and money orders. Just give us a call at 423-722-5152 and we can process your order promptly. In the event you attempt to reach us outside of our operating hours, please leave us a detailed message and we will return your call at our earliest opportunity.

THE BEST FLOWING, BEST QUALITY SBF ALUMINUM HEADS ON THE MARKET FOR THE MONEY.

This sale is for one fully assembled set of heads.

The springs in these heads are set up to operate with hydraulic roller cams up to .600 lift. For those running flat tappet cams, see our other listings for these heads with the part number NKB-FORD-272.

The NKB FORD aluminum heads have 62cc combustion chambers with 190cc runners, 2.02/1.60 stainless valves. These heads are not built by Procomp, and have no association with them in any way.

Spark plugs are in standard Ford location.

We certainly know where to draw the line with low end products, and we continue to eliminate parts that we once accepted but that eventually had problems. Sometimes it's not that a particular product has had a problem that leads to its elimination; something better just comes along. The NKB cylinder heads are that "something better" coming along. Considering the price is only slightly higher than our former line of heads, this has to be the best value in a set of cylinder heads we have ever offered.

Our cylinder heads are made from AC4B alloy and tempered to T6 standards. Details about this alloy are in the lower section of this ad.

A breakdown of the part number.

The NKB stands for "New Kid on the Block"; 190 represents the intake runner size, 274 designates the use of longer valves, and dual springs with a damper setup for hyd. roller cams. You will also see the heads listed with the number 274. The 272 designates the use of standard length valves with single springs with a damper, setup for hyd. flat tappet cams. We also have the valve train setup for solid roller cams, and will have the number 583 rather than 272 or 274. Be absolutely certain of what you need before buying. Feel free to call us if you need assistance deciding what you need for your build.

Below is our flowchart on these heads. All tests were performed on a Superflo 1020 bench by our expert head builder. We stand behind the accuracy. We have noticed many other sellers posting what we consider to be false flow numbers on the heads they are selling. We find this to be nothing short of outright fraud. Of course, flow numbers can vary a few points depending on equipment used and testing methods, but not by 15-25 points. Notice the low lift flow numbers produced by our new heads. That is as important as the upper lift numbers, and it's why these heads produce so much peak power and torque. We are very impressed with the flow numbers of our new heads.

|

NKB Ford 190cc

|

|

Lift

|

Int.

|

Exh.

|

|

100

|

65

|

59

|

|

200

|

113

|

100

|

|

300

|

164

|

140

|

|

400

|

214

|

160

|

|

500

|

245

|

168

|

|

550

|

254

|

169

|

|

600

|

259

|

170

|

|

650

|

261

|

169

|

See our other listings for these heads with our Competition Series PBM valves.

Our NKB Ford heads have been designed especially for us. After receiving many recommendations from our engine builders, we came up with the best quality, best flowing heads on the market relative to cost. The only way you're going to get a set of heads that flow as well or better will be to spend at least double the cost or more. These heads are excellent in design and quality. Our choice of hardware and precision assembly also contribute to the performance and reliability of the heads.

ONE YEAR WARRANTY, UNLIMITED MILEAGE.

Here is a rundown on the hardware used in these heads and the assembly process.

Comp High Performance Dual Springs, Part Number 987-16

Our Comp springs are 1.43 diameter, with an inner spring and internal damper. Others are using springs that are much smaller in diameter. Smaller diameter springs may be in the correct spring pressure zone, but they usually have a shorter life. Comp springs are made in the USA. All of our engines using the NKB heads use these springs. Spring failures are near non-existent.

Our PBM valves are high temp stainless steel.

PBM/Erson stainless steel race series valves, swirl finished one piece undercut, the same valve we have used for years. Our cost on these valves is nearly double the price of some low cost valves on the market. These are made from high grade non-magnetic stainless. We know for a fact that many head builders use the low cost valves. It is very rare we ever encounter a problem with our valves. We also offer the PBM Competition Series valves in our 66cc heads for the Ford heads.

Below is a copy of one or more of our invoices from Engine Parts Warehouse showing a recent large order for our PBM valves. We have removed the price and our account number for privacy reasons. This is the best way we can prove to our customers that the valves we use in our cylinder heads are genuine PBM products.

Assembly Procedure

We hone all of the bronze valve guides with a ball berry flex hone to establish not only perfect clearance, but also a semi cross hatch finish for oil retention. We finish off with a natural bristle brush. The heads are then placed in our parts washer and cleaned with high pressure hot water, then pressure dried. Before installing the valves, we apply a heavy coat of engine assembly lube to the valve stems. The coating on the valve stems is essential to protect the bronze guides from gaulding on initial startup.

Our next step is to set the spring pressure to a predetermined pressure using a spring height checking device, most suitable for street rod use. The springs we are using allow for a near perfect seat to nose ratio. Be warned that some sellers of aftermarket heads may not be checking the installed height when assembling the heads, and may not be setting them up to the correct pressures. We have a full scale machine shop with several very knowledgeable engine builders that know and fully understand how to properly assemble a set of heads. Combine the possibility of poor assembly methods with incorrect or low grade hardware, and it is easy to see how failures can result.

We purchase most of our valve train hardware in bulk for our engine program. Below is a copy of one of our invoices from Comp Cams showing several of our rather large purchases of valve train hardware. We have removed the price and our account number for privacy reasons. This is the best way we can prove to our customers that the valve train products we use and sell are genuine Comp Cams products.

IMPORTANT NOTE CONCERNING ROCKER ARM STUDS.

If you have been a regular shopper with us, you will have noticed we do offer some knock-off products that are made off-shore. We do also sell many products made in the USA. We have always been very particular as to the quality and workmanship of such products, while considering the cost. We scrutinize our products very carefully and refuse to sell products that simply don't meet our standards. We have now eliminated another of the low cost knock-off products from our line. The low cost imported rocker arm studs have shown numerous problems unlike those in the past. We have looked at several others on the market, and still find many issues with them that are not acceptable.

Many of the studs had run-out in the shaft of up to an eighth of an inch. This caused major problems with rocker alignment, and depending where the position was when the stud tightened up, would determine the direction of the rocker misalignment. If the warped stud was facing toward or opposite the valve, then the roller tip would would not be centered to the valve tip. This would then create a loss of lift and cause increased wear on the valve tip.

If the warped stud tightened up in a side to side position, then this would allow the rocker tip to be cocked on the valve tip. This would then side load the valve tip with undue pressure, creating a serious wear problem on the side of the valve tip and create excessive wear on the valve guides in the heads. This also side loaded the rocker trunnion and front roller, creating an excessive wear issue in the roller rockers.

We also found a difference in the tread pitch and depth compared to the ARP studs. The rocker studs in an engine are under a tremendous upwards pull and improper thread design may cause the studs to pull out of the head. The ARP studs screw into the heads with a very precise fit and feel.

After thoroughly comparing the ARP studs and several off shore models, I am convinced that we will never offer the off shore studs again, regardless of the price difference. They were never as bad in the past as what we're seeing now. This run-out was most likely caused by improper heat treating methods.

We have rejected many products that are outright junk and would cause serious issues in your engine only to see other sellers offering those same exact products. It's all about learning where to draw the line.

Studs and guide plates are NOT included. Other sellers may include these items but rest assured, they are usually not suitable for these heads. We use nothing but the Dart adjustable guide plates and ARP rocker studs when we build an engine using these heads, as they allow for perfect alignment of your rockers. See our other listings for a full selection of accessories.

See our other listings for valve train related items that you may need for your project. The part number for the correct studs and our Dart guide plates to be used with these heads is ? for those running 3/8's size roller rockers, and for those with 7/16's roller rockers the part number is ? These kits are available in our other listings.

We are glad to offer many great low cost items, as well as the high end products, but will always give careful consideration to quality, functionality, and overall value.

IMPORTANT NOTE, MUST READ!

We have noticed several sellers offering these heads with a one size fits all valve springs for dual use on hydraulic flat tappet and hydraulic roller cams.

We are sure this is not the proper way to setup the heads.

If they have this one size fits all setup somewhere in the middle spring pressure values of what is required for a hyd. flat tappet and a hyd roller cam, then it would be too much for the hydr. flat tappet cam, and create a wear issue. Putting too much pressure on flat tappet cams is a sure way to kill the cam. If these middle of the road springs were used on a hyd. roller cam, then the spring pressure would be too low. Valve float and its damaging effects, along with a loss of performance, are sure to occur.

We use the correct spring for your setup and it is never the same on a hyd. flat tappet as it would be on a hyd. roller cam. As mentioned above, the spring requirements between a roller cam and flat tappet cam are dramatically different. Even the odd ball solid flat tappet cam has its own unique setup depending on the lift. The one size fits all hardware claims also to work on these cams. We know of several sellers offering this insane setup to unsuspecting buyers, and it's not the proper way to set up a set of heads. We would not even consider using a spring setup like this, and believe me, the simplicity of it is appealing.

Our cylinder heads are made from AC4B alloy and tempered to T6 standards. You may have heard the alloys 355 and 356 being used on many heads. The alloy used on our heads is similar but slightly different. The AC4B alloy is commonly used by automakers in Europe and Japan. Take notice of the Rm value. This value indicates the tensile strength of an alloy. As you can see, it's higher than all the other common alloys in this chart. It's no surprise as to why we have never experienced a failure of any kind with these heads. Zero failures in the casting, zero failures in the seats and guides. We have sold over 5000 pair of these heads over the past four years.

|

List of Standard Alloy Characteristics

|

Alloy +B4: H16

|

AC4B

|

AC4C

|

AC4CH

|

AC4D

|

AC7A

|

|

Mechanical

properties

|

Rm

(MPa)

|

345

|

285

|

260

|

320

|

245

|

|

R0.2

(MPa)

|

250

|

225

|

157

|

240

|

105

|

|

A

(%)

|

1.6

|

7.3

|

16.8

|

4.1

|

5.3

|

|

Temper

|

T6

|

T6

|

T6

|

T6

|

F

|

|

Features

|

High strength, small elongation

Castability: good,

for general purposes

|

Castability: good

Pressure resistance, corrosion resistance: good

|

Castability: good

Mechanical properties: good

|

Castability: good

Pressure resistance: good

|

Corrosion resistance: excellent,

anode oxidized

Castability:

not good

|

|

Examples of

applied parts

|

Crank cases,

cylinder heads,

and manifolds

|

Hydraulic parts,

transmission cases,

aircraft parts,

lighting components, etc.

|

Wheels,

engine parts,

hydraulic parts,

aircraft parts, etc.

|

Cylinder heads,

crank cases,

fuel pump bodies, etc.

|

Parts for overhead contact lines,

parts for ships,

business machines,

and lighting components for aircraft

|

|

|

|

|

|

Guide plate recommendation.

Pushrod recommendation

Stud Girdle recommendation.

NKB-190cc RUNNER SIZE 62cc COMBUSTION CHAMBERS FOR FORD ENGINES

Intake Valve Dia: 2.02"

Intake Port volume: 190cc

Intake Port Dim: 2.0" x 1.12"

Int Port Location: Stock

Intake Gasket: Felpro# 1262

Head Gasket: Felpro# 10112

Exh Valve Dia.: 1.600"

Exh Port volume: 70cc

Exhaust Port Dim:

Exh Port Location: Stock location & bolt pattern

Exhaust Gasket: Depends on what type exhaust you're using. Best to try and match up the gasket to your header or manifold

Flow, Intake: See chart above.

Flow, Exhaust: See chart above.

Head Bolts: ARP 154-3601

Rocker Studs: ARP 100-7101 (for 7/16" Rocker Arms)

Manifold: Most any. Our line of intakes fit very well on the NKB heads.

Milling: Min. Down to 58.5cc or 64.5 = .060" See info in this listing for details on this.

Pistons: Most aftermarket pistons.

Push Rod length:

Push rod Guide Plate: Comp Cams 4835-8 (for 5/16" Diameter Pushrods)

Retainers/Locks: Chromoly Steel Retainers, with 10° Comp brand machined locks are used on all of our heads.

Spark Plug: Autolite #3923 14mm x 3/4" reach

Spring Pockets: 1.550" OD (.030" deeper max)

Springs: Comp 1.43 large size outer diameter with internal damper.

Valve Length: 5.015" (+.200") for hydraulic roller cams.

Valve Stem Dia: .3415" - 11/32"

Valve Train: STD SBF 3/8" or 7/16" stud mount

Valve Guides: 1/2" OD Int = Mag-bronze Exh = Phos-bronze (.002" press)

Valve Guide length: 1.950"

Valve Guide clearance: .0014" - .002" (with our .3415 dia. valve stem)

Valve Guide Spacing: 1.890" moved .030" from stock

Valve Seats: Hardened Ductile Iron, .006" press

Valve Seat dim. Standard

Valve Seat angles: Int = 32° - 45° - 60° - 70° Exh = 37° - 45° - radius

Stud Girdle:

Torque: Head Bolts = 65 ft/lb

Rocker Studs = 55 ft/lb

Manifold = 30 ft/lb

Block Use: Any SBF Iron or Aluminum

Weight: 59-61 lbs fully assembled pair.

A final note...Skip White Performance...About Us